Suntuff Protective Roof Coatings Developed By Professional Paint Chemists

- Developed by professional paint chemists for roofers

- Very high quality resins used (some nano)

- High quality tints /organic oxides in our formulations

- Long lasting – 10 to 15 years (conditions apply)

- Tried and trusted

- Anti graffiti, Two pack paints

- Protection against rust, corrosion and dirt resistant

Looking for Suntuff Protective Roof Coatings? Enquire Now

High Performing Roof Coating Products

Suntuff Protective Roof Coatings in collaboration together have created a range of high performance roof coating products that are made for Roofers by professional paint chemists.

Suntuff Protective Roof Coatings are uniquely formulated, tried and trusted to withstand the tough Australian climate. A unique product that’s created how the professionals like it.

Suntuff Protective Roof Coatings

Mark Robinson, one of the directors NuRoof coatings, has been in the chemical industry for over 30 years and an industrial chemist at Nu Roof Resin/ RGL Adhesives.

For the last 12 years formulating roof coatings and has an acute knowledge of manufacturing roof, wall and driveway coatings.

Barry Marson, Director at Suntuff Protective Coatings has been in the roofing industry for over 31 years and roof coatings production more than 12 years.

In this time, Barry has created unique water-based products that replaced the old solvent-based traditions, introducing Nano technology* coatings in our top of the range coatings and sealers.

Protect & Improve The Lifespan Of Your Most Valuable Asset

It has smaller particle sizes in the resin which makes it more dirt resistant on top coats and better penetration for sealers allowing you to protect and improve the lifespan of your valuable assets.

Advantages Over Oppositions Products / Coatings

- Our coatings are very high polymer solids formulations (compared to other manufacturing companies) this gives the coatings extra durability, longer lasting with high UV resistance etc.

- Contains NO Inert fillers on TOP COATS They are manufactured using Australian made polymers (where possible), giving long lasting protection in the harsh Australian climate.

- Better pigmentation system using the latest technology with very high quality organic tints that are burnt oxides from the ground This results in consistent, highly pigmented colours with high UV resistance. We use organic oxides (from the ground) in our formulations, ensuring a better quality material which helps to stop fading.

Products Lab Tested and Proven Roof Coating Products

Before any new products are released they are regularly and extensively tested in NATA registered laboratories against the latest Australian standards and repeatedly benchmarked against leading opposition products.

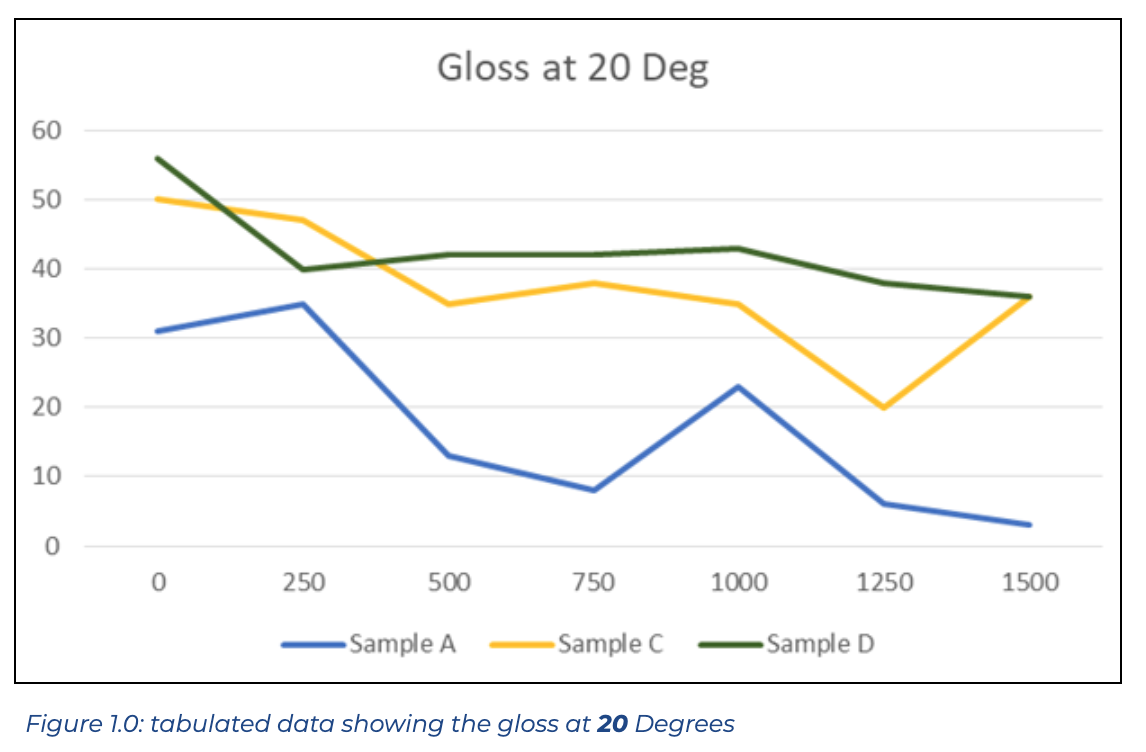

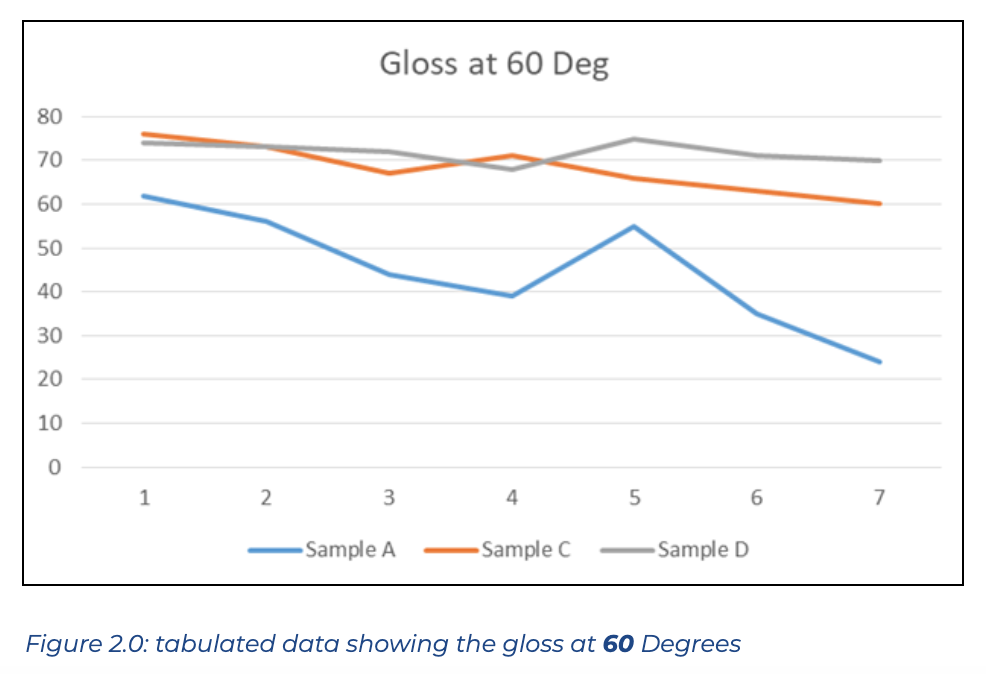

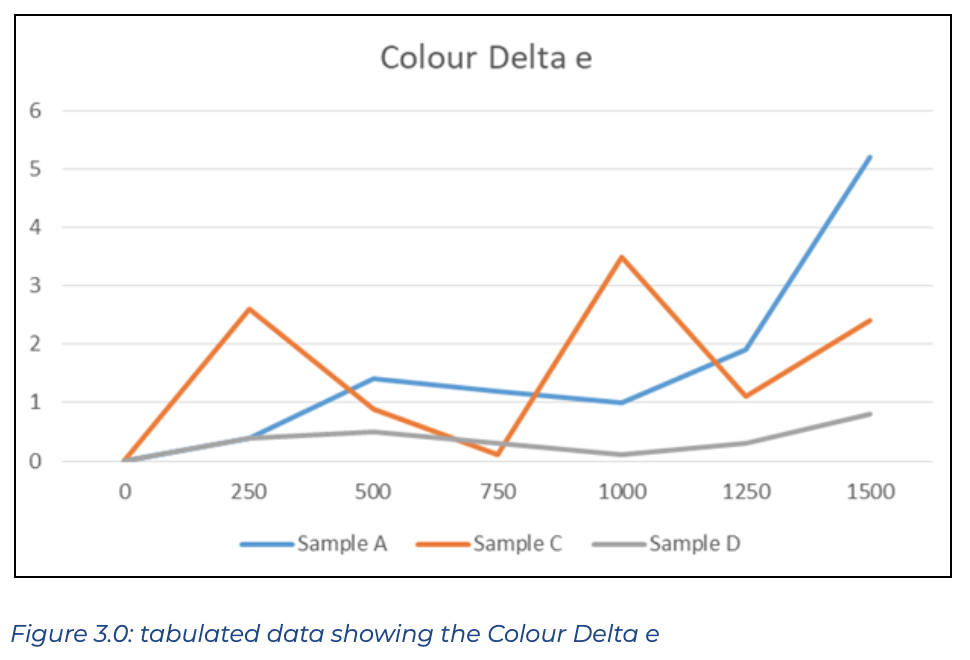

The tabulated data below shows the performance of the Nu Roof Coating vs leading opposition products. The Delta E figure represents colour change over time. A result of less than 0.5 is generally considered to be undetectable to the naked eye.

Tabulated Data from NATA Registered Laboratory QUV Testing

Nu Roof Resins/RGL regularly test their resins to ensure they are up to standard.

We regularly benchmark our products against the leading oppositions’ products and that we are happy to put our product up against any opposition.

Sample D: RGL Adhesives, Standard roof coating Sample A: Leading opposition 1, Standard Roof Coating Sample C: Leading opposition 2, Premium Roof Coating

Technical Data Sheet: Roof Tile Paint

Typical Properties

Physical form Coloured Thick liquid

Odour Mild characteristic odour

pH value at 25 °C 7.5 approx

Solubility in water Mixes with water

Density at 25 °C 1.0 approx

Boiling point Approximately 100 °C

Flash Point Not available

Description

- Water based coating for airless spray application to roof tiles

- Excellent UV resistance

- Rapid cure

- Wide range of colours available

- Resistant to microbial attack

- Non-Hazardous

- Non-Toxic

Looking for a paint? Enquire Now

Application

Application Methods

- Thoroughly clean the tiles using industrial pressure cleaner (3500 – 4500 psi.)

- Flexi-point ridge capping and replace broken tiles

Suntuff Coatings Tile Paint is designed to be applied using an airless spray system or similar. The coating system has been developed to be easy to use and to provide long-lasting colour, gloss and protection to the roof. The drying time will vary depending on the weather conditions and on the heaviness of the coating being applied. A three to six coat system is recommended. We recommend using a 6/23 to 6/27 spray tip for best results for tiles, as this is an industrial/commercial grade paint.

Application Process

First Coat: CT Primer (Tile Roofs)

1 x Fungicide/pre treatment to stop fungi growing through the new paint job.

1 x CT Primer is a high build undercoat. Its function is to penetrate into and seal the roof surface providing a sound surface for the next coat to bond to

.1 x High build filler or Base coat for badly worn tiles

First coat for metal roofs

1 x Metal Primer is a high build anticorrosive undercoat or EP primer for colourbond roofs.

Its function is to chemically bond to and protect the roof surface. The anticorrosive pigments in the metal primer prevent corrosion of the metal taking place underneath the paint film. Metal primer and EP Primer has been formulated to provide exceptional adhesion using Nano Technology and allows it to stick to the metal roof and not come off

Colour Coats

2 x coats of Ultrashield, Dirtshield or Thermal coating in your chosen colour.

Two colour coats provides a high film build for extra durability and longer lasting protection.

All coatings are durable, tough coating with exceptional UV resistance and proven performance in harsh climates.

Final Coat is for Extra Protection

1x coat of Nano Glaze to help reduce fading (by 5 – 6 years)

Nano Glaze is a clear protective glaze for enhanced gloss and UV resistance. An extra layer of protection to extend the life of your investment.

A low sheen version of the Nano Glaze is available for metal roofs to restore the original Colorbond look.

Disclaimer

The information contained here is given in good faith and is intended to be of assistance to users. The performance of Suntuff Protective Coatings product is dependent upon its correct preparation, application onto a sound surface and attention to the instructions on the label.

The wide variety of surface conditions makes it impossible for the company to assume liability for any loss, consequential or otherwise, arising from the use of this product. Should the product be found defective, our liability shall be limited to the replacement of the product only.

We reserve the right to amend specifications and application techniques without prior notice.

Any technical information ring, Darren on 0427 226 651 or Barry on 0434 706 666